Tools & Equipment

What is a Stonemason and how to become one

What is a Stonemason?

A stonemason is a person working in the profession of preparing and cutting different types of stone to build, create and repair homes, buildings, historical landmarks, monuments headstones and more. The work of stonemasons has been around for more than 12,000 years and dates back as one of the oldest occupations in history. Stonemasonry is the professional term for the job whereby stone and rocks are skilfully crafted into precise shapes to restore, repair or create new stone structures.

Traditionally stonemasons worked solely with natural stones including, marble, granite and limestone. However, engineered stone is the latest development that is now frequently used. The stonemason trade has become more specialised in kitchen, bathroom and interior decors leading to a rise in the use and availability of artificial and engineered stone. Artificial and engineered stones are commonly made from a range of materials incorporating cement, sand and natural blends of crushed stone, combined with advance technology to create replica stone pieces.

What does a stonemason do?

Stonemasons cut and shape stone blocks to be used as a finished surface or built into structures. Different types of stone can be used for a range of applications, including sandstone, limestone, granite, dolomite, quartzite, and marble. Stonemasons can have a range of specialisations and work across a variety of applications from kitchen benchtops, bathroom vanities to commercial projects like lobbies and counter tops, Stonemasons may also carry out heritage restoration or corrective work.

Daily Tasks and Duties of a Stonemason may include:

- Using precise measurements and reading technical drawings.

- Measuring kitchen benchtops and surface areas for quotation

- Cutting and polishing bathroom vanities and kitchen benchtops from a range of natural and engineered stone.

- Installing kitchen bench tops or large format slabs for home décor or commercial applications

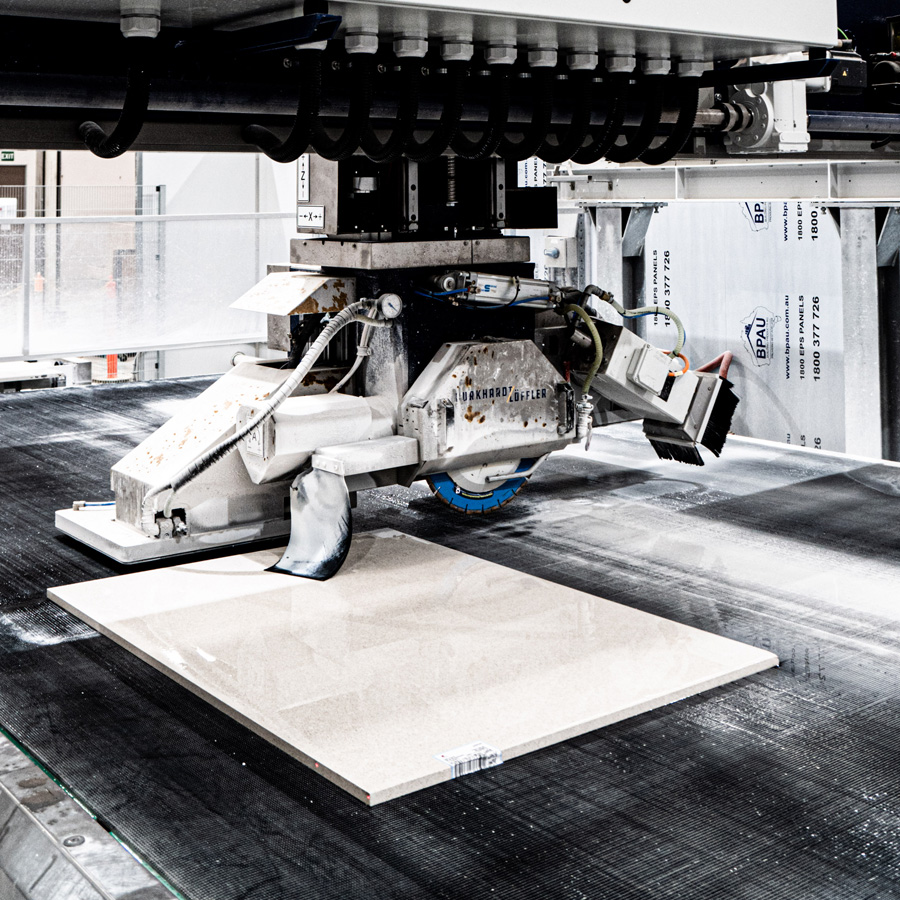

- CNC machine, bridge saw processing and using CAD drawing software to create a range of surfaces from bathroom and kitchen benchtops to tiles and fire hearths.

- Working both independently and in a team-oriented, collaborative, environment.

- Use machinery to cut and polish natural and artificial stone for commercial and domestic use.

- Hand tools are used to shape and polish stones and slabs.

- Cutting and carving of headstones, including fine details and lettering specifically for monumental masons.

- Laying stones according to construction plans and project specifications.

- These tasks can take place offsite at a stonemason warehouse or on location at the site of installation, both indoors and outdoors.

- Mathematical and problem-solving skills are frequently used as a stonemason.

- Appreciating the stone that is being worked on or helping to select the best stone for the job.

Tools of the Trade

Stone masons use a range different tools to assist in the fabrication, installations and maintenance for natural and engineered stone, some of the fundamental tools used in stonemasonry include:

Abrasive Polishing tools can be used on wet polishing machines for Granite, Marble and Sintered Stone surfaces. CDK’s range of abrasive polishing tools have the ability to produce an array of finishes including gloss, honed, polished, brushed, sandblasted, silk, extra soft and more.

Computer numerical control routers (CNC) are cutting machines controlled by a computer. Routers and drills are used on these machines to cut efficient and accurate curves on a range of materials including natural and sintered stone.

Diamond blades are a saw blade that has been produced with fine quality diamonds segments crafted into its edges, the blades are made with the latest diamond technology and are available in a wide range of sizes to make it capable of cutting Natural Stone, Engineered Stone, Quartz and Ceramics.

Stone Adhesives are made for mitering, seaming, laminating, rodding and repairing all types of stone. CDK Stone stock a widespread range of high-quality adhesives to be used for both natural and engineered stone as well as other civil engineering applications requiring superior bond strengths.

CDK Stone is proud to offer an extensive range of stonemasonry tools, the full range can be viewed here.

Different types of Stonemasons

Highly trained and skilled stonemasons may work across a range of the following roles.

Residential/ Commercial Stone Mason

Stone masons that work on residential and commercial projects are the most common and primary type of stone mason in Australia.

Quarryman

Quarryman work in the quarry directly sourcing different types of stone from the earth. The stone is usually split into sheets or chunks by cutting against or across the natural grain. This type of stone mason is predominately found in areas of the world like Carrara in Italy where stone is extracted for use.

Banker Mason

A banker mason uses project designs and building plans to cut and shape stone into their required designs.

Carver Mason

Carver Masons have high artistic skill, they use these skills to create fine working patterns, designs or carve large shapes and animals.

Memorial Mason

Memorial masons design, cut and carve headstones, along with creating fine lettering and details.

How to become a stonemason?

To become a stonemason in Australia you are usually required to complete an apprenticeship. There are two different pathways to follow:

- The Certificate III in Stonemasonry, with a choice to focus on different key learning areas including monuments, which involves cutting, engraving and installing monuments in places such as parks and cemeteries.

- Undertaking an Apprenticeship learning directly from a stonemason factory. Stone mason apprenticeship training usually includes learning skills such as laminating, edge polishing and sink cut outs in consultation with your employer. Each state has different rules and regulations, and a specific stonemason licence may be required. Check with your state government building authority.

Education

Find our more about the education required to become a Stonemason:

Working Conditions

Stonemason’s work may take place at the stone mason factory or onsite both indoors and outdoors. The working requirements can include strenuous tasks including lifting heavy materials, standing, kneeling, or bending for long periods. Despite working sometimes in dusty, dirty conditions stonemasonry roles are unique opportunities to progress your career in a fast-paced environment. Being considered a higher risk occupation it is important to ensure the stonemason factory is equipped with the correct safety gear and follow all recommended safety guidelines.

CDK Stone support the rights for stonemasons to work in a safe environment, we sell a range of effective safety equipment needed for processing natural and artificial stone.

Please visit the relevant safe work authority in your state for more information about industry regulations and insights. Refer to your local workplace safety regulator for safety details.

CDK Stone stocks a range of tools and equipment to assist stone masons in the fabrication, installations, and maintenance for natural and engineered stone, plus a range of general consumables for other trades. View our range here.