Machinery

Launching GMM’s latest bridge saw

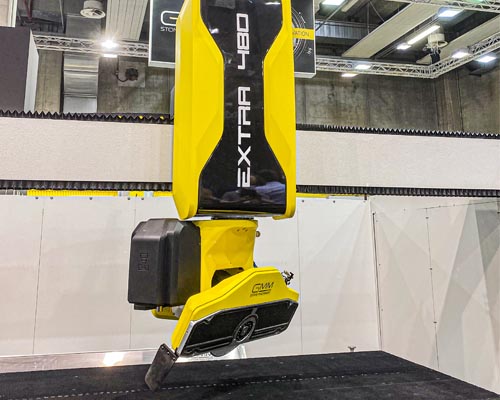

GMM Extra 480

Upgraded machine quality, Z-axis of 480mm and greater cutting accuracy

CDK Stone, which has represented the top Italian bridge saw manufacturer GMM for 30 years, launches the new Extra 480 CNC bridge saw in Australia in March. This model supersedes the Extra 400, which proved to be one of the best-selling machines globally for the kitchen countertop sector.

GMM is the leading manufacturer of bridge saws in the world, and is known for very high-quality machines, ease of use and reliability, says James Clark, CDK Stone’s General Manager, Business Development – Tooling and Equipment.

The company will launch the new model at their Fabrication Innovation Day in Sydney on March 16, and the machine will be then available in all states.

“The 480 is a monobloc machine and is the latest incarnation of the range, and the build quality has been upgraded,” Mr Clark says. “It’s one tonne heavier than the 400 model, so it’s a very solid machine with a larger table and a more rigid bridge and Z-axis.

“This assists with greater accuracy, especially at the high cutting speeds now possible with of new diamond blade technology.”

Improved user interface

The user interface has also been upgraded, from a 15-inch touchscreen on the 400 model to a 21-inch full colour touchscreen. This uses similar technology to mobile phone screens, with the ability to pinch and zoom into workpieces.

Extensive information is available at a glance on the home screen, meaning operations are far more efficient than switching between the previous subfolders.

The Extra 480 standard software called Combined Cuts from CAD now includes contouring software and drilling as standard, with additional software options available such as profiles and shapes, coring, bas-reliefs, lettering, and offline programming.

The EXTRA 480 features an optional lateral spindle separate from the blade’s main spindle motor. Operators can use a blade to do the majority of a cut, then route out the corners and tap holes, allowing more complete jobs to come off the machine.

Previously, the machine operator needed to manually load a router or drill bit, or optionally have a 2 or 4 position automatic tool changer. Having two separate spindles on the bridge means no tool change is required. As well as the saw blade and separate Lateral spindle the EXTRA 480 can still optionally be fitted with an additional 4 position tool changer with additional tools for drilling and milling.

While the machine is equipped with all required software for programming jobs, it can also be operated with the SeKON modular CAD/CAM software available through CDK Stone. SeKON has been developing software for the production of slab materials, particularly stone, for more than 20 years. It offers an outstanding production management system for stone installers, with all programs for automatic manufacturing contained in a modular software solution.

The GMM Extra 480 has remote Tele-Service that can be accessed by CDK Stone’s technicians around Australia, as well as GMM Italy. The company now has 19 technicians, supported by service managers, service case managers, three software experts and a machinery parts department.

“We invite those in the kitchen manufacturing industry to inspect the new Extra 480 in any state or territory,” Mr Clark says. “It’s a significant step up from the 400 model, and we expect it will become another best seller for GMM.”