Machinery

New SeKON Software

New Software Alert

Best-in-class vein matching software that is efficient and functional

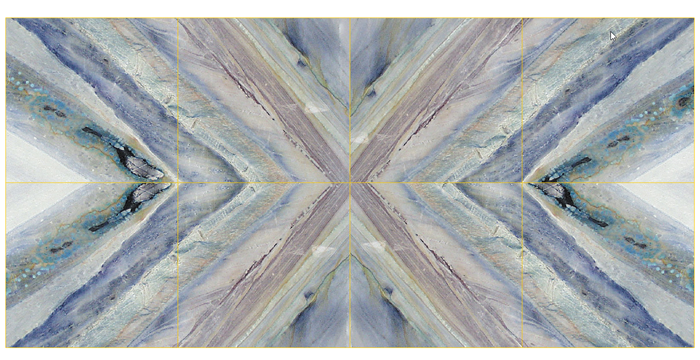

Vein matching natural and engineered stone slabs for high-end kitchens, bathrooms, floors and accent walls is attracting growing interest among designers and end consumers. This growing trend has been inspired by vein matched stone in the best contemporary projects around the world.

Vein matching stone involves the stone being processed to showcase its natural veins; then working with the veining of the stone slabs to create a coherent connection of the vein and colours gradients across different applications and shapes within a design. This effect crafts unique designs that range from subtle to the dramatically expressive.

Once a very time-consuming, manual and costly process, new software developments have simplified the process and created more efficient methods to achieve a precise vein match effect.

“Vein matching has traditionally been a very time-consuming and therefore expensive process,” says Jonathan Height of CDK Stone. “However, new software developments like CDK Stone’s Vein Matching and nesting modules with digital scanning have made the process substantially less time-consuming and more precise.”

As the process becomes more efficient and less cost-restrictive, “designers and end-users are now rapidly growing the demand for vein matched execution because of the very distinctive visual impacts it creates.”

CDK Stone offers one of the most sophisticated solutions on the market for vein matching.

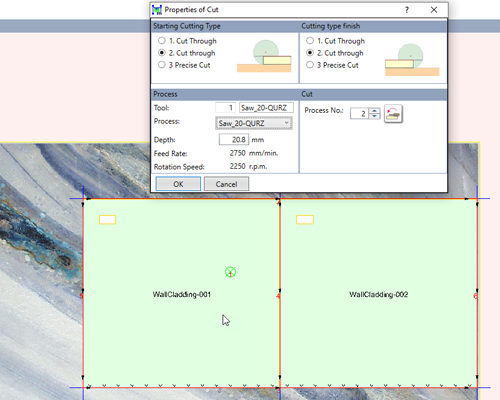

A two-in-one solution, for precise and effective processing from imagery to machine execution. Using high-end cameras or slab scanning technology, the stone slabs are digitized. The slab pictures and workpiece layouts are imported into the SeKON TOP nesting and vein matching software. The workpieces are nested on the slab picture overlay. The vein matching view allows the placement and ability to shift the workpieces on the slabs to achieve the highly desired connection of veins and colour patterns on the final project layout. Larger jobs like a U-shape kitchen, floors or wall cladding that require veins connecting over multiple slabs can be easily executed. The software is designed to import and work with as many slabs as required for the project. Advanced pre-programming allows multiple stone slabs to be vein matched to reflect the client’s preferred design.

The software’s practical functionality has been designed to fully support the stone fabrication process with the ability to view stone cuts before being made, lay out the entire design with digitised slabs and can show the customer the final design execution plan. Industry-leading stonemasons using the Vein Matching technology by CDK Stone speak to the accuracy it creates in the fabrication process, the time it saves and the reduced wastage that occurs. These benefits can save thousands of dollars in the usage and placement of premium stone in the design while flawlessly aligning the veining across the project.

Traditional vein matching was laborious and involved a high level of expertise to carefully align the stone veining and colour tones across the project. CDK Stone’s new software technology can use multiple slab images throughout the design, giving a flawless matching execution without the traditional risk and pain of manually selecting slabs for placement.

“The advanced vein matching module brings the best in industry vein matching processes from the factory floor to the office to create a scalable solution that is practical to use and efficient to execute” says Jonathan.

Mistakes and risks are substantially reduced with final production designs that can be produced in 3D format so they can be viewed by designers and end customers. This ensures the final vein matched solution meets customers’ expectations.

The advanced, vein matching technology is world-leading with its ability to integrate with a wide range of stone machinery and production facilities that are using SeKON software. This makes integration available to all, from smaller stonemason operations to larger fabricators.

SeKON Software is Germany’s leading stone CAD/CAM software and can be installed on a wide range of stone processing machinery from all the top manufacturers. CDK Stone has tailored solutions for a small factory wanting to increase their efficiency and accuracy of vein matching on a single saw, right up to the largest of plants processing on multiple Bridge Saws, WaterJets and CNC work centres.

Learn more about sekon software